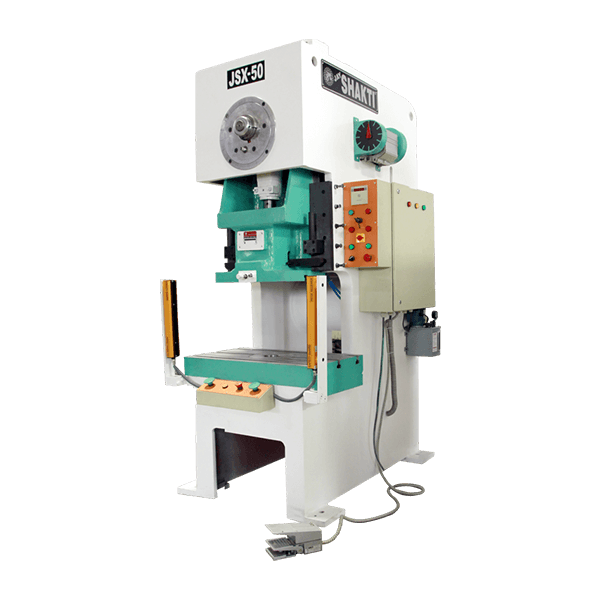

Standard Feature

Product Description

It is composed by thick steel sheets cut by sinking welded and stress-relived before machining, so as to eliminate any residual tensions. The dimensions study is carried out according to methods of calculations in order to assure the maximum strength against any deformation even under the highest rated load.

Fully enclosed, well-designed, single-geared, with main shafts supported at three bearing points located close to each other impart sturdiness and eliminate cantilever action. Precision cut, fully enclosed gears running in oil bath with flywheel and back shaft running in anti friction bearings provide silent and vibration-free operation.

• Non geared also available upto 100T

It is obtained from a forged piece of carbon steel. Prior to the machining, the shaft undergoes an ultra-sound inspection and a chemical and metallographic test, Shaft is ground finished on bearing surfaces, all main Bearings are of Heavy Walled Nickle phosphorous Bronze, which are hand scrapped.

Graded cast Iron Slide, runs on six independent extra long gibs with replaceable liners, bearing clearance bronze on the gibs are easily adjustable. The massive slide presents wide area and long gibs providing high degree of centering and rigidly at extension of the adjustment.

A lockable selector switch of ONCE, INCH and CONTINUOUS mode of operation is provided. The press is equipped with a highly reliable Dual Solenoid Valve, which prevents faulty operation by electrical lockout. ‘Top Stop’ to stop the press at top Dead Centre. Two Hand Engagement Device, Emergency Stop are some of the other standard features. The electric equipment is in line with the latest safety

Pneumatic counter balancers are provided to counter the weight of the slide and toolings, which help in taking up the bearing clearance and ease slide adjustment, as well as smooth movement of the slide and effective braking.

The single – disc clutch has the advantages like; a continues joint-free stroke, no adjustment is needed to correct wear on the facings, it is self-ventilating which increases it performance, its operation is safe and fast, etc.

The Automatic Lubrication of all moving parts of the machine is controlled by a central pump through capillary distributive system.

Capacities and Specification

| Model | JSX-16 | JSX-25 | JSX-32 | JSX-40 | JSX-50 | JSX-63 | JSX-80 | JSX-100 | JSX-125 | JSX-160 | JSX-200 | JSX-250 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity KN | 160 | 250 | 320 | 400 | 500 | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 |

| Stroke Adjustable | 8-63 | 8-80 | 8-80 | 8-88 | 8-100 | 8-100 | 8-110 | 8-125 | 8-125 | 8-160 | 20-160 | 20-160 |

| Stroke/Minute (SPM) | 75 | 70 | 70 | 65 | 60 | 60 | 55 | 50 | 45 | 40 | 40 | 35 |

| Shut Height (SDAU) | 210 | 230 | 230 | 250 | 275 | 300 | 340 | 360 | 400 | 425 | 450 | 450 |

| Adjustment of Slide | 50 | 63 | 63 | 70 | 70 | 70 | 75 | 80 | 80 | 125 | 125 | 125 |

| Slide Area(LRXFB) | 300×200 | 350×250 | 350×250 | 400×350 | 450×375 | 500×400 | 550×425 | 600×450 | 650×520 | 710×600 | 900×700 | 950×800 |

| Punch Hole (Dia X Deep) | 40×70 | 40×70 | 40×70 | 50×85 | 50×85 | 50×85 | 55×85 | 63×85 | 63×85 | 63×105 | 80×110 | 80×110 |

| Bolster Area (LRXFB) | 600×355 | 630×400 | 630×400 | 800×450 | 850×500 | 900×550 | 1000×600 | 1100×630 | 1150×680 | 1220×750 | 1250×800 | 1300×850 |

| Bolster Thickness | 80 | 85 | 85 | 110 | 110 | 120 | 125 | 140 | 140 | 165 | 180 | 180 |

| Height from Floor to Bolster | 800 | 800 | 800 | 800 | 800 | 900 | 900 | 900 | 900 | 900 | 1000 | 1000 |

| Frame Inside | 375 | 420 | 440 | 500 | 550 | 600 | 625 | 675 | 700 | 850 | 875 | 925 |

| Main Motor (Geared) HPXP | 2×4 | 3×4 | 3×4 | 5×4 | 5X4 | 7.5×4 | 7.5×4 | 10×4 | 12.5×4 | 15×4 | 20×4 | 25×4 |

| Slide Adjustment Motor HPXP | – | – | – | – | – | 0.5×4 | 0.5×4 | 0.5×4 | 1×4 | 1×4 | 1×4 | 2×4 |

| Air Pressure (Kg./cm2) | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 |

| Overall Dimension (FBXLRXHT) | 1100 x 850 x 2000 | 1320 x 1010 x 2150 | 1350 x 1020 x 2200 | 1450 x 1100 x 2350 | 1500 x 1150 x 2375 | 1600 x 1250 x 2650 | 1660 x 1300 x 2750 | 1850 x 1400 x 2950 | 1900 x 1450 x 3050 | 2150 x 1625 x 3350 | 2200 x 1650 x 3500 | 2300 x 1750 x 4100 |

Note:-

- All dimensions are in mm.

- Power supply 400/440 volts, 3 phase, 50 cycles.

- Cutting Capacity based on (45 kg./mm² UTS m.s.)

- Special sizes other than above offered on request.

- Through our technical department continual Devploment, Variations in size and performance are subject Without notice.